LUBRICATING SYSTEM - L4

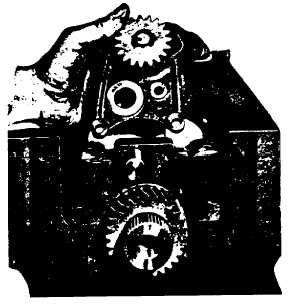

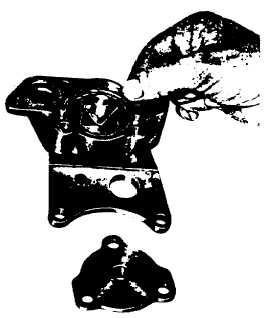

Fig. L.5.

Removing the Lubricating Oil Pump.

2.

Remove the key from the keyway of the drive

shaft.

3.

Unscrew the three screws which secure the end

plate to the pump and remove the plate.

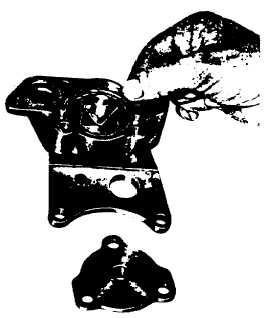

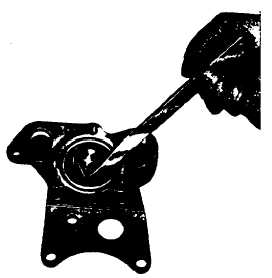

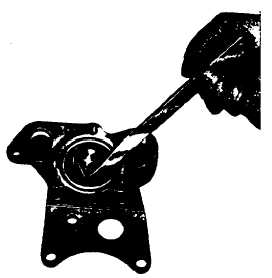

Fig. L.6.

Removing the "O" Sealing Ring from the Oil Pump.

4.

Carefully remove the drive and driven rotors

from the pump body.

5.

Remove the "O" sealing ring from the pump

body (where fitted). See Fig. L.6.

Inspection

1.

After thoroughly cleaning all the parts they

should be examined for signs of cracking, wear

or corrosion.

2.

Install the inner and outer rotors in the pump

body, bearing in mind that the chamfered edge

of the outer rotor enters the pump body first.

3.

The clearances are checked as shown in Figs.

L.7., L.8 and L.9.

NOTE: The relevant clearances for these

dimensional checks are given on Page B.8,

they are the clearances applicable to a new

pump and are intended to be used as a

guide. Should a lubricating oil pump be

worn to such an extent that it adversely

effects the working oil pressure, then a

replacement pump should be obtained. The

component parts of the pump itself are not

supplied individually,

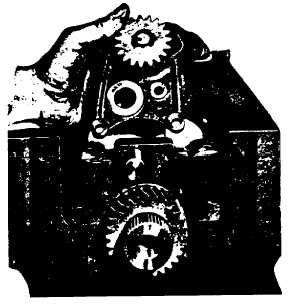

Fig. L.7.

Checking Clearance between Inner and Outer Rotor.