SERVICE MANUAL

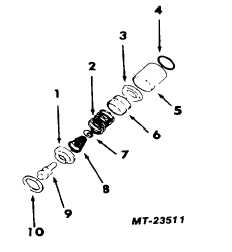

Legend for Fig. 23

1

Outlet Port

2

Spring

3

Cap, Top

4

Screw, Cap 3/8"-16x1"

5

Cup, Filter

6

Strainer

7

Nut, 3/8"-16

8

Washer, Lock 3/8"-ext. tooth

9

Nut, 3/8"-16

10

Rod, Support

11

Washer, Lock 3/8"-ext. tooth

12

Nut, 3/8"-16

13

Screw, Cap Socket hd. 3/8"-16x1l"

14

Gasket

15

Spindle

16

Seat, Ring

17

Heater

18

Thermostat

19

Spring

20

Port, Exhaust

21

Ring, Retaining

22

Spring

23

Cup, U

24

Ring, O

25

Piston

26

Port (UNL) Unloader

27

Nut, Unloader

28

Sleeve

29

Cap, Bottom

30

Gasket

31

Gasket

32

Plate, Support

33

Body

34

Deflector

35

Washer

36

Ring, Packing

37

Spring, V

38

Filter

39

Spring

40

Gasket

41

Valve, Safety

42

Spindle

43

Gasket

44

Nut

5.

Remove complete unloader valve assembly

including copper gaskets (10).

Excessive accumulation of oil in the unloader assembly

indicates that the air compressor requires attention.

6.

Examine unloader valve assembly. If the

unloader sleeve (5) is nicked, wrinkled or has axial

scratches, the unloader valve assembly should be

replaced. The unloader valve assembly if clogged should

be cleaned with a good cleansing solvent.

7.

Do not remove retaining ring (7) from unloader

spindle (9) since they are serviced as an assembly with

spring (8) and seat ring (1).

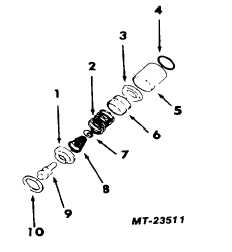

Fig. 24 Contents of Unloader Valve Kit

1

Ring Seat

6Piston

2

Spring, Large

7Ring, Retaining

3

Cup, U

8Spring, Small

4

Ring, 0

9Spindle, Unloader

5

Sleeve

10Gasket (2 Req’d.)

8.

Install new "U" cup (3) in groove of unloader

piston. Lips of "U" cup should face away from

spring seat. Do not use sharp tools that may mar

or score parts.

9.

Apply a light film of Item 1 in LUBRICANT

SPECIFICATIONS to O-ring (4) and position on

unloader nut.

10.

Position the two copper gaskets (10) together

and lightly coat exposed surfaces with Item 1 of

LUBRICANT SPECIFICATIONS. Then position

lubricated gaskets on shoulder of ring seat (1).

Gaskets should be on face opposite the spring

(8).

11.

Place gaskets (10) followed by seat ring as-

sembly into bottom cap (Item 29 of Fig. 23).

12.

Install unloader sleeve (5) in unloader port

against the seat ring. Be sure the 12.7 mm (I")

diameter cross hole is next to the seat ring.

13.

Position large spring (2) in the sleeve (5) with

large diameter coil against seat ring.

14.

Insert unloader piston (6) into unloader sleeve.

Lips of U-cup (3) must face out with spring seat

toward spring. The unloader spindle (9) and seat

ring (1) is a mated assembly and should not be

disassembled. If either the ring seat or spindle is

nicked, the entire mated assembly must be

replaced as an assembly.

CTS-4079 - CHAPTER XIV - Page 15