SERVICE MANUAL

8.

Wash all remaining parts in a commercial

solvent making sure all surfaces, bores, ports

and

passages

are

clean

and

dry

before

reassembly.

The heater and thermostat assembly in the AD-2

end cover are non-serviceable. Do not remove

the thermostat cover. Should this assembly

become defective, the end cover must be

replaced.

Fig. 18 AD-2 End Cover Assembly with

Purge Valve Assembly Removed

Fig. 19 Purge Valve Assembly Disassembled

Reassembly

1.

Lubricate the piston O-ring and install it on the

piston.

2.

Lubricate the piston bore and install the piston.

3.

Install the purge piston return spring and

piston.

4.

Install the purge valve in the large cap nut so

that the rubber portion rests on the metal seat of

the cap nut.

5.

Secure the valve to the piston using the 1/4"-20

capscrew and lockwasher and torque to 5.5 N.m

(50 in. lbs.).

6.

Lubricate and install the two cap nut 0- rings.

7.

Lubricate the cap nut threads and the cap nut

bore of the end cover and install the cap nut;

torque it to 19.8-27.5 N.m (180- 250 in. lbs.).

8.

Secure the exhaust diaphragm to the exhaust

cover using the No. 6-32 phillips head screw and

diaphragm washer.

9.

Secure the exhaust cover to the purge valve hex

head cap nut using the No. 6-32 phillips head

screws.

10.

Lubricate and install the large diameter 0- ring

around the end cover assembly.

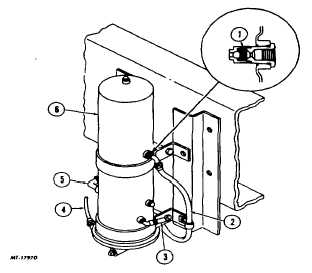

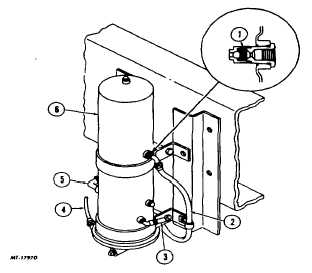

OUTLET PORT CHECK VALVE ON AD-2

The one-way check valve located in the outlet port of

the AD-2 dryer assembly is replaced as a complete

assembly. The removal and installation procedure is as

follows (Refer to Fig.

20).

1.

Set parking brake by applying the control valve.

Fig. 20 Typical Air Dryer Installation

1

Check Valve Assy.

2

Supply to Air Reservoir

3

Pressure Relief Valve

4

Governor Control Line

5

Air Source From Compressor

6

Air Dryer Assembly

CTS - 4079 - CHAPTER XIV - Page 11