SERVICE MANUAL

15.

Insert a 12.7 mm (i") diameter rod or equivalent

through the exhaust port in the bottom cap (Item

29 of Fig. 23) and into the cross hole of sleeve

(5) to maintain alignment. If the cross holes are

not aligned, the unit will not operate.

16.

Apply a non-hardening sealing compound to

thread of the unloader valve nut (Item 27 of Fig.

23) and install the nut. Tighten nut to 81 Nm (60

ft. lbs.) maintaining the alignment of the cross

holes of sleeve (5). Overtightening of the

unloader nut will result in damage to the

unloader assembly.

17.

Remove the alignment rod inserted in step 15.

18.

Reinstall the governor control line to UNL port in

center of unloader nut.

19.

Reinstall in air input line from the air com-

pressor.

20.

Connect electrical lead for the heater.

21.

Test

unit

using

the

instructions

listed

in

SERVICE CHECKS.

Servicing Deflector Assembly

There are several indications which may mean

that the deflector assembly needs servicing:

Compressed air was cooled by the unit but no

longer is cooled properly.

Water exhausted by the CR BRAKEMASTER is

brownish or brown particles are exhausted.

A piece of the deflector is caught in the unloader

valve assembly causing it not to operate

properly.

These situations can be caused by several

conditions. Check the TROUBLE SHOOTING GUIDE to

make sure that the probable cause is a malfunctioning

deflector assembly. If it is a malfunctioning deflector

assembly, the following are the instructions for replacing

this deflector assembly.

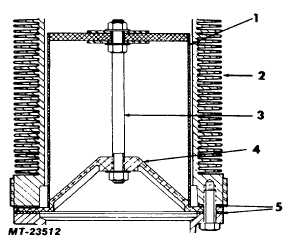

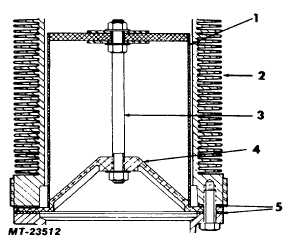

Refer to Fig. 25 for numbers in parenthesis.

1.

Refer to General Instructions.

2.

Disconnect air compressor service line at inlet

port.

3.

Disconnect governor control line from unloader

nut (Item 27 of Fig. 23).

4.

Disconnect wire from heater assembly.

Fig. 25 Contents of Deflector Kit

1

Deflector

2

Body Tube

3

Rod, Support Assy. (Refer to

4

Plate, Mounting

5

Gaskets

5.

Remove the eight cap screws (Item 13 of Fig.

23) retaining bottom cap to body (2).

6.

Remove bottom cap and deflector assembly.

On older units the deflector is secured to the bottom cap.

If this is the case, the deflector should be

removed from the bottom cap by means of

removing the four screws holding the deflector to

the bottom cap. The feet of the bottom cap (to

which the deflector was attached) must be

removed.

7.

Remove all traces of old gasket(s) material from

gasket surfaces of bottom cap and body.

Discard old gaskets. Be careful not to scratch or

mar gasket surfaces.

8.

Wash bottom cap and inside of unit with

cleaning solvent.

9.

Position new gasket (5) on top of surface of

deflector mounting plate (4).

10.

Position second new gasket (5) on gasket

surface of bottom cap.

11.

Align bolt holes and position assembly against

bottom gasket surface of body tube (2). Use of

gasket sealant is NOT recommended.

CTS-4079 - CHAPTER XIV - Page 16