SERVICE MANUAL

12.

Insert eight cap screws to attach bottom cap to

body tube and deflector assembly. Tighten

alternately and evenly to 20.3 Nm (15 ft. lbs.). If

unit previously had old style deflector attached to

bottom cap, use the eight longer cap screws

contained in the deflector replacement kit.

13.

Reconnect the air line to the inlet port (this line

leads from the compressor service port).

14.

Reconnect the governor control line to the

unloader port in unloader nut (Item 27 of Fig.

23).

15.

Reconnect the wire to the heater.

16.

Test the unit following the instructions listed in

SERVICE CHECKS.

Servicing Check Valve Assembly

There are several indications which may mean

that the check valve needs servicing:

Air is exhausted from exhaust port when

compressor is in stand-by mode.

System air pressure bleeds off rapidly when air

using equipment is not being operated.

Compressor goes into stand by mode but cycles

rapidly.

Compressor attempts to build pressure but

system pressure will not build up.

Safety valve opens.

These situations can be caused by several

conditions. Check ’the TROUBLE SHOOTING GUIDE to

make sure that the probable cause is a defective

assembly. The following is the procedure for servicing

and replacing the check valve assembly.

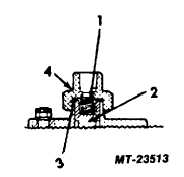

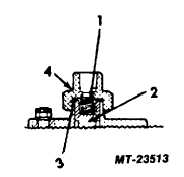

Refer to Fig. 26 for numbers in parenthesis.

1.

Refer to the General Instructions.

2.

Disconnect air line at outlet port at top of unit.

3.

Remove top nut (4). This nut is spring loaded.

4.

Remove copper gaskets (3), spring (1), and

check valve spindle (2).

5.

Clean and dry entire check valve area and top

nut (4).

6.

Position new check valve spindle (2) in top cap

with tapered end down.

Fig. 26 Check Valve Assembly

1

Spring

3

Gaskets

2

Spindle

4

Nut

7.

Install spring (1) in check valve spindle.

8.

Position new copper gaskets (3) in nut (4) and

rub a small quantity of grease on the gaskets to

help them keep their position in the top nut.

9.

Thread nut on to top cap and torque to 81 Nm

(60 ft. lbs.). Top nut (4) is not included in check

valve replacement kit.

10.

Reconnect the air line to the outlet port. The

safety valve (Item 41 of Fig. 23) cannot be

serviced and it is recommended that it not be

removed from the top cap. If the safety valve

was removed, apply non-hardening sealant to

threads of top cap.

11.

Test the unit following the instructions listed in

SERVICE CHECKS.

Servicing Filter Assembly

Although the filter assembly of the unit is

designed to require little or no servicing, it is a good

practice to service the filter assembly when performing

service on the other filters located on the vehicle. This

servicing can be accomplished in one of two ways, either

replacing the entire filter assembly, or by servicing the

filter assembly. In most cases, simply servicing will only

be necessary. The following are the steps for servicing

the filter assembly. If the entire filter assembly is being

replaced, those steps preceded by an asterisk (*) can be

eliminated.

Refer to Fig. 27 for numbers in parenthesis.

1.

Refer to the General Instructions.

2.

Remove air line at outlet port.

CTS-4079 - CHAPTER XIV - Page 17