SERVICE MANUAL

3.

Turn vehicle wheel and at the same time rotate

adjusting screw until brake shoes are tight

against drum.

4.

Back off adjusting screw just enough to eliminate

drag.

5.

Make and hold full brake application to fully seat

brake shoes against drum and note the angle

between slack adjust and push rod. This angle

should be a minimum of 90 degrees or more.

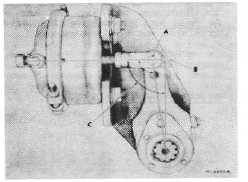

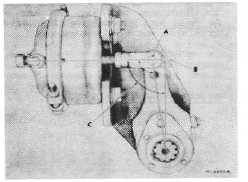

If the foregoing adjustment or relining of brake shoes

does not establish an angle of near 90 degrees between

push rod and slack adjuster with brakes applied (Fig. 2),

then maximum force against slack adjuster cannot be

obtained. Readjust push rod as follows:

1.

Disconnect slack adjuster and push rod. Do this

carefully because slack adjuster may be turned

toward

brake

chamber

with

considerable

pressure.

Fig. 2 Brake Chamber and Slack Adjuster

A

Slack Adjuster More Than 90° in Released

Position

B

Applied Position

C

Angle Should be 90° in Applied Position

2.

Loosen lock nut on clevis and thread clevis onto

push rod toward brake chamber for several

turns.

3.

Reconnect slack adjuster and push rod with

clevis pin.

4.

Make a full brake application and check angle

between slack adjuster and push rod. If 90

degrees or slightly more is not obtained with

brakes applied, repeat adjustment until angle is

satisfactory.

The desirable situation is to bring brake shoes against

drum just as the slack adjuster attains the near 90

degree position (Fig. 2).

MANUAL SLACK ADJUSTER OPERATION TEST

Slack adjusters should rotate freely without binding when

the brakes are applied and when the brakes are

released, all slack adjusters must return to the released

position freely and without binding. The slack adjusters

must be adjusted so that the angles formed by brake

chamber push rod and center of slack are near 90

degrees as described in BRAKE ADUSTMENT.

BRAKE CHAMBER SERVICE TEST

Operational Test

Apply and release the brakes, observing the brake

chamber push rod. The chamber push rod should move

out promptly and return to the released position freely

without binding.

Leakage Test

1.

Apply the service brakes and apply soap solution

to the chamber clamping area. If leakage is

noted, tighten the clamp ring bolts and if leakage

does not stop, the chamber must either be

reconditioned or replaced.

2.

With the service brakes applied, check for

leakage through the diaphragm by applying a

soap solution to the push rod opening and drain

holes on non-pressured side of chamber. No

leakage is permissable. If leakage is evident,

the chamber diaphragm must either be replaced

or complete chamber replaced.

LUBRICATION

Brake camshafts and slack adjusters should be

lubricated every five months or 26,000 km (16,000

miles). Refer to LUBRICATION Section for type of

lubricant. Do not overlubricate. Slack adjusters without

fittings require no lubrication. The provision for

lubrication may differ on slack adjusters. Some have

zerk fittings while others utilize pipe plugs or snap-in type

plugs or covers.

When brake linings are replaced, apply a thin coat of the

same lubricant to brake shoe anchor pins and

camshafts. Do not overlubricate.

CTS-4080W - Page 4