SERVICE MANUAL

DESCRIPTION

The

term

"foundation

brake"

is

given

to

those

components at wheels which actually do the braking.

This includes such items as brake shoes, lining, anchors,

drums and spider or backing plate. Although the slack

adjusters, cam and followers are not directly known as

components of the foundation brakes, they

will be covered herein.

MAINTENANCE

A regular schedule for periodic cleaning, lubrication,

adjustment and inspection should be established, usually

based on past experience and type of vehicle operation.

It is difficult to determine an exact maintenance interval

(time or mileage) since vehicles will be used in a wide

variety of operational applications and conditions.

To compensate for lining wear, brakes should be

adjusted frequently to maintain satisfactory operation and

efficient brakes.

Refer to BRAKE ADJUSTMENT for detailed adjustment

procedures.

Drain air reservoirs regularly as required. Local

conditions govern frequency. Dry climates require less

attention than humid areas, where it may be necessary

to drain reservoirs daily.

When draining air reservoirs, let all air bleed off and be

sure all drainage stops.

For details for the air system, refer to the appropriate air

brake system section.

BRAKE ADJUSTMENT

Brake adjustment can be a contributing factor of brake

complaints.

Proper

brake

adjustment

must

be

maintained. Do not overlook brake adjustment on the

trailer either. Brake balance on trucks and tractor trailers

is essential for good braking.

Periodic checking of push rod travel or brake adjustment

is essential for good braking. Push rod travel should be

checked every 6,000 km (4,000 miles) to determine if

adjustment is necessary. Push rod travel should be kept

at a minimum without brakes dragging.

Inspect brake lining every 19,000 km (12,000 miles) or

every 12 months, whichever occurs first. When brake

lining or blocks are worn to within 1.6 mn (1/16") of

rivets, brake lining must be replaced.

If brake lining is satisfactory, adjust brakes in the

following manner making brake adjustment, one wheel at

a time, with all drums in place and all slack adjusters

connected to chambers.

These instructions apply to manual adjustment type

slack adjusters.

1.

With wheels raised and parking brake released

so that wheels will rotate freely, check each

brake chamber push rod to make certain that it

is in fully released position. To do this,

disconnect push rod at slack adjuster. If push

rod moves toward (released) brake chamber,

turn worm shaft and rotate slack adjuster toward

push rod until clevis pin can be reinstalled.

2.

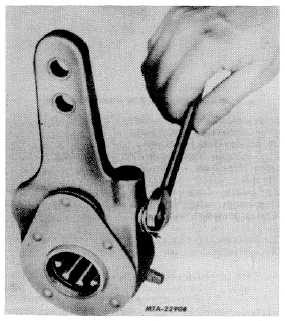

Disengage locking sleeve on worm shaft or

adjusting screw by depressing spring loaded

sleeve with a wrench (Fig. 1).

Fig. 1 illustrates the locking sleeve in its

disengaged position. Be sure sleeve is held in,

disengaging the adjusting screw when making

adjustments.

Use either an open or socket wrench when

making adjustment. Make certain locking sleeve

is held in, thereby disengaging the locking

mechanism. Never use a wrench on the sleeve

portion.

Fig. 1 SIack Adjuster Locking Sleeve on Adjusting Nut

CTS-4080W - Page 3