IV. STEERABLE DRIVE END DISASSEMBLY

5.

Disconnect the steering tie rod by removing the

cotter pin, castle nut and then, while prying

between the tie rod end and the tie rod arm,

sharply strike the side of the tie rod arm radially

to the tie rod end tapered stud.

6.

Disconnect the brake hose.

7.

Remove the four bolts that hold the upper

kingpin bracket to the spindle yoke.

8.

Lower the transmission jack about two inches

and roll the outer section of the steerable drive

end away from the axle.

F.

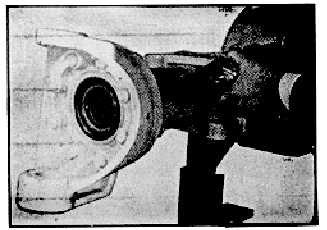

Inner Axle Shaft Removal

1.

Perform only step E above and then pull the axle

shaft and universal joint from the axle housing.

(See fig. 24.)

2.

Or after steps B, C, and D, pull the axle shaft

and universal joint from the axle.

G.

Lower Kingpin Bracket and Kingpin Removal

1.

The lower kingpin ball stud and the lower kingpin

bearing are exposed for inspection after steps B,

C, and D or after step E alone. (See fig. 25.)

Back off lower kingpin lock nut. Remove four

nuts and washers retaining the lower kingpin

bracket and tie rod arm to the spindle yoke. The

bracket may now be removed.

2.

A tool for rotating and holding the lower kingpin

ball stud may be made by welding a nut onto a

capscrew the head of which fits the socket in the

end of the lower kingpin ball stud. A standard

socket or wrench can then be used on the nut to

turn the capscrew and kingpin stud. An allen

wrench may be used.

3.

Screw the kingpin stud from the bracket.

H.

Lower Kingpin Bearing Removal

After Section IV-E, and only if the bearing is

being replaced, drive the bearing out of the

suspension yoke by pushing on the lower kingpin

disc.

Fig. 24

Fig. 25

Fig. 26

-12-