SERVICE MANUAL

CONNECTING RODS, PISTONS, RINGS & SLEEVES

Section 5

NOTE: If all counterbore ledges of one particular

engine are to be counterbored to the same depth,

take measurement of aft counterbores and set up

counterboring tool on lowest counterbore ledge, to

insure clean-up of all counterbores.

c.

Hold onto handle (1) and pull out on plunger

(9).

d.

Slowly and gently lower tool holder into

counterbore, to avoid damage to the tool

bit.

e.

Engage larger diameter of tool holder into

counterbore and allow tool bit to rest on

counterbore ledge.

f.

Loosen locking screw (10) and rotate

adjusting

nut

(2)

in

a

CLOCK-WISE

DIRECTION

until

tool

bit

clears

the

counterbore ledge.

g.

Tighten locking screw.

h.

Assemble

hold-down

cap

screws

and

washers (5) through adapter plate (6) into

cylinder block finger-tight.

i.

Tool holder must rotate freely.

j.

Torque cap screws to 45 N•m (33 Ibf-ft).

Tighten each cap screw only a small

amount before final torquing. Then cross-

tighten in diagonal sequence.

6.Measure depth of counterbore as follows:

a.

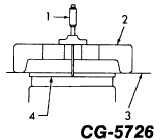

Using a depth micrometer (1, Fig. 26)

measure from the top surface of adapter (2)

to deck of crankcase (3) and record

measurement.

b.

Then, measure from top surface of adapter

plate to counterbore ledge (4) and record

measurement.

c.

Subtract No. 1 reading from No. 2 reading,

and this is the depth of the counterbore

ledge as exemplified below.

EXAMPLE:

No. 1 Reading -

Top of Adapter Plate

to Counterbore Ledge

2.125"

No. 2 Reading -

Top of Adapter Plate

to Deck of Cylinder Block

-1.750"

Depth of Counterbore =

.375"

Figure 26. - Depth Measurement of Counterbore

1. Depth micrometer

2. Adapter plate

3. Deck of engine block

4. Counterbore ledge

7.Operate counterboring tool as follows:

a.

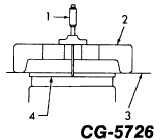

Loosen locking screw (1, Fig. 27).

b.

Rotate adjusting nut (2) in counter-

clockwise direction until tool bit is resting on

the lowest part of the counterbore ledge

and there is clearance between the housing

(5) and the adjusting nut.

c.

The distance between the housing and

adjusting nut equals the amount of material

that will be removed from the counterbore

ledge.

d.

The adjusting nut has graduated markings

to estimate the amount of the cut. Each

mark is 0.03 mm (0.001 in.)

NOTE: Never attempt to remove more than 0.13 mm

(0.005 in.) of material at one setting.

CGES-185-3

PRINTED IN UNITED STATES OF AMERICA

Page 24