SERVICE MANUAL

CRANKSHAFT, MAIN BEARINGS, FLYWHEEL & CRANKCASE

Section 6

5.

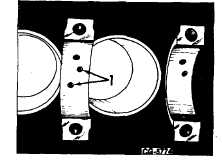

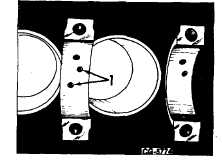

Inspect the 12 piston oil jet tubes used in

Turbocharged Engines. Be sure they are open

and clean as shown in Fig. 19.

Figure 19. - Piston Oil Jet Tubes

1.

Oil jets

NOTE: DO NOT remove oil jets unless damaged.

6.

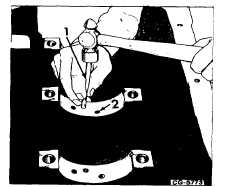

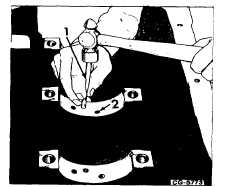

If tubes are damaged replace as follows:

a.

Remove damaged tubes with a pilot driver

(1, Fig. 20) as shown.

b.

Install new oil jet tubes with the same pilot

driver shown in Fig. 20.

c.

The jet tube (when installed) must not

project above the surface; but must be

recessed 3 mm (1/8 inch) below the

surface as shown in (2, Fig. 20).

Figure 20. - Removing/Installing Piston Oil Jet Tubes

1.

Pilot driver

2.

Oil jet tube

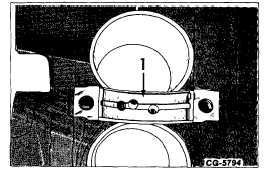

d.

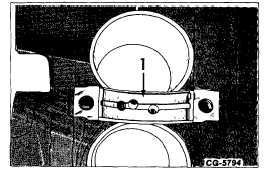

The top half of the main bearing insert (1,

Fig. 21) is slotted to provide a flow of oil to

the Jet tubes and camshaft bushings as

shown.

Figure 21. - Main Bearing Insert - Old Style Shown

w/OFFSET Piston Oil Jet Tube Holes

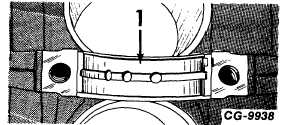

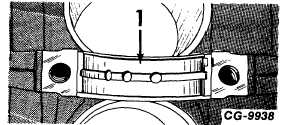

Figure 21A. - Main Bearing Insert - New Style w/Piston

Oil Jet Tube Holes in Line

7.

Repairs for coolant or oil leaks in crankcase

casting can be performed in areas shown in

Figure 21B only. Instructions are as follows:

Restrictions:

a.

No repairs may be made within one inch of

an internal rib, wall or boss casting.

b.

Casting cracks can not be repaired.

c.

Leak to be repaired must be within tap drill

diameter.

d.

Maximum plug size allowed for repair is

1/4-18 NPTF.

e.

Leaks to be plugged (repaired) must be at

least 3 inches apart.

CGES-185-3

PRINTED IN UNITED STATES OF AMERICA

Page 16