SERVICE MANUAL

CRANKSHAFT, MAIN BEARINGS, FLYWHEEL & CRANKCASE

Section 6

INSTALLATION

Prior to Crankshaft installation, check the Crankcase for

trueness as follows:

1.

Using a lint-free cloth, wipe the bearing supports

of the crankcase free of oil.

2.

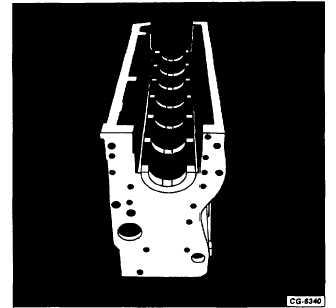

Support the crankcase bottom side up as shown

in Fig. 24 using wooden blocks to level it.

Figure 24. - Crankcase Bottom-Side-Up View

3.

Install the upper halves of the bearings (bearings

with oil hole in center) on the crankcase.

a.

If the original bearings are to be

reinstalled, be sure they go to the

positions

from

which

they

were

removed.

b.

The nibs of the bearings must fit into

the notches in the crankcase bearing

supports.

4.

Apply Prussian Blue on the crankshaft main

journals and lower them carefully and evenly

onto the bearings. DO NOT install the bearing

caps and lower bearings.

5.

Rotate the crankshaft approximately one-half

revolution.

6.

Remove the crankshaft evenly and inspect the

upper bearings for an even transfer of bluing

from journals to bearings.

7.

Replace any bearings that do not show an over-

all even bluing.

NOTE: It is advisable to replace all bearings with

new, if one of the originally used bearings has to be

replaced.

8.

When satisfied that the crankcase is in good

order and free from any distortion and burrs

around the upper bearing seats proceed as

follows:

a.

Clean all bluing from the bearings and

crankshaft journals.

b.

If using the original bearings coat the

bearing surfaces with a small amount

of clean engine oil.

c.

Install the bearing halves (bearing with

oil hole in center).

d.

Carefully install the crankshaft.

CGES-185-3

PRINTED IN UNITED STATES OF AMERICA

Page 20