SERVICE MANUAL

CRANKSHAFT, MAIN BEARINGS, FLYWHEEL & CRANKCASE

Section 6

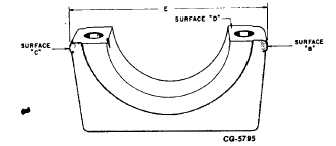

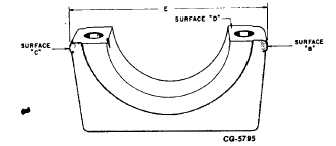

7.

Subtract dimension "A" of the OLD cap from

dimension "A" of the NEW cap and record the

difference. Mill or grind this amount from

surface "C" (Fig. 27) of the new cap. Dimension

"A" of both caps will now be equal.

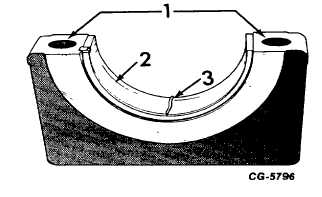

Figure 27. - Bearing Cap Finished Length

Surface "C"

Surface "B"

Surface "D"

NOTE: Surface "C" (Fig. 27) must be held square

with surface "D" and parallel to the bearing bore.

8.

Mill or grind surface "B" (Fig. 27) of the new cap

until the dimension "E" 153.67153.72 mm

(6.050-6.052 in.) shown from surface "C" to "B"

is obtained.

NOTE: Surface "B" (Fig. 27) must be held square

with surface "D" and parallel to the bearing bore.

Fit Main Bearings in Main Bearing Caps as follows:

1.

Install a new bearing in a new bearing cap or the

original bearing in the original bearing cap, as

called for.

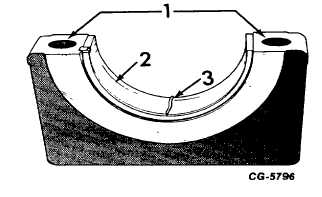

2.

Check the bearing clearance as follows:

NOTE: DO NOT turn the crankshaft during this

procedure.

a.

Clean the bearing surface and the

exposed half of the crankshaft journal.

Be sure these surfaces are free of oil.

b.

Place a suitable length of 0.010 inch

virgin lead wire or a piece of

Plastigage across the bearing surface

as shown in Fig. 28.

Figure 28. - Position of Virgin Lead or Plastigage

1.

Surface "D"

2.

Bearing

3.

Plastigage

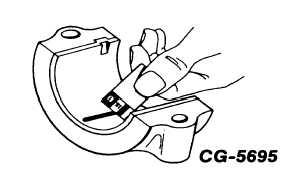

c.

Install the bearing cap and torque the cap

screws to 155 N•m (115 Ibf-ft).

d.

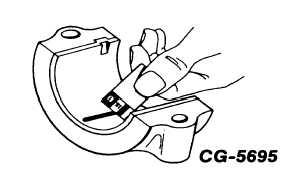

Remove the bearing cap. When virgin

lead is used, measure the crushed

thickness with a micrometer and record the

results. When Plastigage is used, the

flattened plastic material will be found

adhearing to either the bearing or the

crankshaft.

DO

NOT

remove

the

plastigage. Determine bearing clearance

by comparing the width of the flattened

plastic with the graduations on the envelope

as shown in Fig. 29.

Figure 29. - Reading Bearing Clearance with Plastigage

CGES-185-3

PRINTED IN UNITED STATES OF AMERICA

Page 22