SERVICE MANUAL

DISASSEMBLY

Section 2

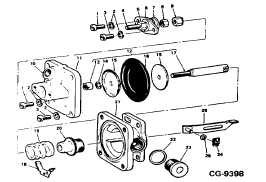

34.

Remove four capscrews and lockwashers from

camshaft bearing retainer on drive end of pump

(Figure 30).

Figure 30.

1. Retainer Mounting Screws

2. Oil Drain Hole

35.

Remove rack screws, lockwashers and retaining

plate (Figure 31). Pull rack out of pump housing.

Figure 31.

1.

Control Rack

3.

Screws

2.

Guide Pin

Injection pump housing is now ready for inspection.

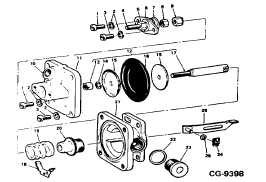

ANEROID

The aneroid (Figure 32) should be disassembled,

cleaned and inspected when the injection pump is

disassembled

or

if

the

aneroid

is

suspected

of

malfunction. The diaphragm assembly must be replaced

if signs of leakage, cracking or hardening exist. Replace

o-ring on diaphragm stop.

IMPORTANT

TO

REPLACE

A

LEAKING

ANEROID

DIAPHRAGM, THE INJECTION PUMP MUST

BE

REMOVED,

THE

NEW

DIAPHRAGM

INSTALLED AND THE INJECTION PUMP

RECALIBRATED. DO NOT ATTEMPT TO

REPLACE

THE

ANEROID

WITHOUT

RECALIBRA-TING THE INJECTION PUMP.

SEEMI-NGLY SMALL CHANGES TO THE

INJECTION

PUMP

CONTROL

RACK

SETTINGS CAN DESTROY THE ENGINE.

Figure 32. Exploded View of Aneroid

1.

Screw

15. Seat

2.

Washer

16. Diaphragm

3.

Screw (w/Seal Hole) 17. Shaft

4.

Pin

18. Clip

5.

Nut

19. Spring

6.

Stop Assy.

20. Bushing

7.

O-Ring

21. Housing

8.

Nut

22. Gasket

9.

Nut

23. Plug

10.

Bushing

24. Clip

11.

Cover Assy.

25. Washer

12.

Shaft Assy.

26. Max. Fuel Aner-

13.

Nut

oid Shackle

14.

Washer

CGES-375

Printed in United States of America

Page 13