SERVICE MANUAL

DISASSEMBLY

Section 2

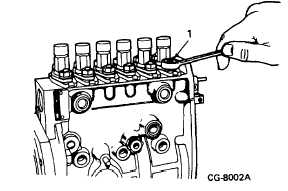

Figure 27. Tappet Removal (If Tappet Depressor Tool

KDEP 1505 is not available)

1.

Tappet Holder

4. Left Lever

2.

Clamping Device

5. KDEP 1067

3.

Right Lever

6. Spacer Plate

Location

b.

Position right lever (3, Figure 27) and then

left lever (4) over first two tappets. Adjust

crossbar (5) up or down to make levers

point up slightly when resting on tappets.

c.

Holding one hand on tappet holder (1,

Figure 27), depress left lever compressing

both springs to unload and remove tappet

holder. Hold onto holder when depressing

tappets because foot of holder is spring

loaded and tool will spring out.

28.

Repeat procedure for the next four tappets.

29.

Remove each roller tappet, lower spring seat,

plunger and spring.

IMPORTANT

KEEP PARTS FOR EACH CYLINDER

TOGETHER.

30.

Position rack so control sleeve ball is in notch of

pump housing (Figure 28).

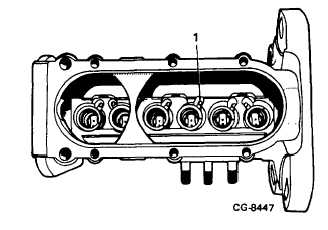

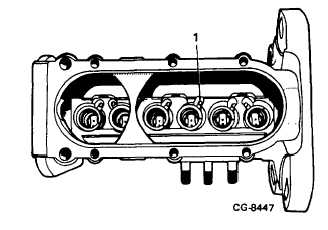

Figure 28. Rack Positioning

1.

Control Sleeve Ball

31.

Remove control sleeves and upper spring seats.

32.

Remove tappet depressor tool (or, if used,

remove pump from spring compressor KDEP

1067).

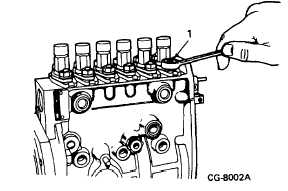

BARREL REMOVAL

33.

Remove barrel flange nuts and lockwashers

(Figure 29) (assembly jig KDEP 1066 may be

used). Remove each barrel from housing. Store

each barrel with its plunger and shims.

Figure 29. Barrel Removal

1.

Flange Nuts

CGES-375

Printed in United States of America

Page 12