SERVICE MANUAL

CLEANING AND INSPECTION

Section 3

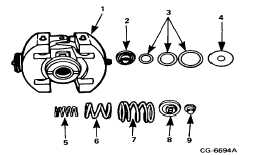

2.

Reinstall

flyweight

springs.

Always

start

preliminary shim pack under governor shims as

follows:

Outer spring: 0.5 (.020") Intermediate Spring: 1.5

mm (.060") Inner Spring: None

Install outer spring seat and adjusting nut.

When

installing

adjusting

nut,

preload

of

governor springs should range from 4 to 10 90

degree "clicks" from flush nut position with

threaded bolt. Preliminary adjustment should be

equal on both spring sets.

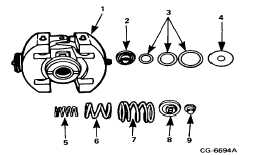

Figure 3. Exploded View of Flyweight Springs

1.

Flyweight Assembly

6.Intermediate

Spring

2.

Lower Spring Seat 7.

Outer Spring (Lo-

ldle)

3.

Adjusting Shims

8.

Upper Spring Seat

4.

Wear Shim

9.

Adjusting Nut

5.

Inner Spring

3.

Inspect damper buffers for damage. If any loose

rotational movement exists in governor weight

assembly relative to the camshaft, replace

buffers. Replace buffers as a set if needed

(Figure 5).

4.

Assemble

prelubricated

buffers

in

damper

retainer and place damper hub on weight

assembly.

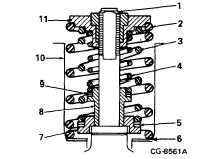

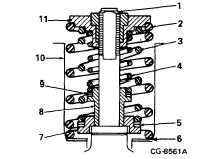

Figure 4. Sectional View of Flyweight Spring Installation

1.

Cylindrical Adjusting

7.

Lower Spring

Nut

Seat

2.

Lo-ldle Spring

(Lower Half)

3.

intermediate Spring

8.

Lower Seat

4.

Hi-Idle Spring

(Upper Half)

5.

Intermediate Adjusting

9.

Inner Spring

Shim

Shim

10.

Flyweight

Assembly

6.

Wear Shim

11. Upper Spring

Seat

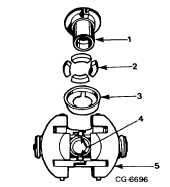

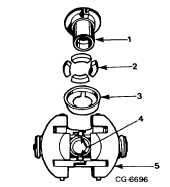

Figure 5. Exploded View of Damper Hub

1.

Damper Hub

4.

Mounting Tang

2.

Buffer

5.

Flyweight

3.

Retainer

Assembly

S-Plate: Sliding parts should operate free of bind; any

grooves or pressure marks on curve should be

smoothed with fine emery.

Guide Bushing: If any parts of the guide bushing are

worn or damaged, replace the complete unit.

CGES-375

Printed in United States of America

Page 3