SERVICE MANUAL

REASSEMBLY

Section 4

PUMP ASSEMBLY

1.

It is suggested that all delivery valves and

plunger and barrel assemblies be inspected and

ready prior to pump reassembly.

While still in assembly jig KDEP 1066 install

copper gasket, delivery valve, spring and washer

into barrel. Tighten delivery valve holder nut with

O-ring to specifications (see torque chart Section

1, Page 10).

IMPORTANT

DELIVERY VALVE HOLDER MUST BE

TIGHTENED (SEE TORQUE CHART,

SECTION 1, PAGE 10) OUTSIDE OF

PUMP

PRIOR

TO

PUMP

REASSEMBLY.

All parts must be returned to their original

position. Clean fuel oil or calibration oil must be

available for lubricating the individual parts prior

to assembly.

BARREL

2.

Install barrel lower O-ring in housing. Install

barrel lower spacer ring in pump housing, if it

was removed, using 9 681 238 902.

3.

Assemble impact cap with snap ring and O-ring

onto barrel. Be sure hole in impact cap does not

line up with spill/fill port in barrel.

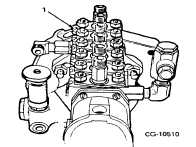

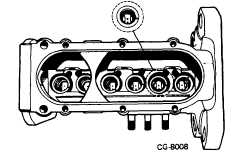

4.

Lubricate O-ring and lower surface of barrel,

and install barrel with adjustment slot on the

barrel flange opposite the control rack (Figure 1).

Figure 1. Adjustment Slot Location

1.

Adjustment Slot

Push down with hand pressure: the barrel

should stay down when pressure is released. If

not, remove barrel and check for pinched O-

ring.

5.

Install spacer plates KDEP 1057 under barrel

flanges and install flat washer, lockwasher and

nuts. Tighten to specifications. Install fitting

locks, flat washer, lockwasher and nuts.

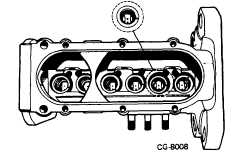

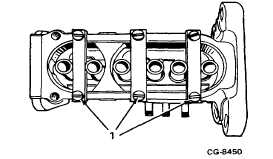

6.

Turn pump upside down. Install each plunger in

correct barrel. Position the notch on the plunger

foot so it points away from the rack, thus sealing

the port (Figure 2)

Figure 2.

1.

Plunger

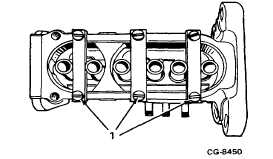

7.

Install plunger retainersKDEP1052 (Figure3).

Figure 3. Install Plunger Retainers

1. Plunger Retainers

CGES-375

Printed in United States of America

Page 1