SERVICE MANUAL

REASSEMBLY

Section 4

8.

Connect air coupling to intake of gallery and plug

return port. Submerge pump housing in an oil

bath and pressurize pump to 5 bar (75 PSI).

Look for leakage (bubbles) from top and bottom

of pump. Any bubbles other than small bubbles

coming from inside plunger retainer tubes

indicates a leak. Correct any leaks found. If no

leaks are found remove air hose, gallery outlet

plug, plunger retainers and plungers.

9.

Loosen barrel retaining nuts and back off so

washers are loose.

PLUNGER AND RACK

10.

Install control rack and fasten retaining plate with

two screws and lockwashers. Check rack for

freedom of movement.

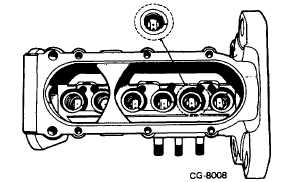

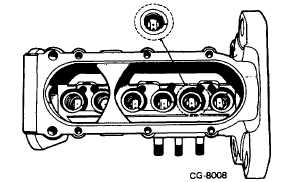

11.

Insert each control sleeve after positioning rack

so that the control sleeve ball will fall into the slot

of the control rack (Figure 4).

Figure 4. Control Sleeve Ball Positioning

1.

Control Sleeve Ball

12.

When all control sleeves are installed, move

rack back and forth to make sure control sleeves

all move freely and together.

13.

Coat each upper spring seat with grease and

stick upper spring seat to spring.

14.

Insert each spring and upper seat into pump

housing.

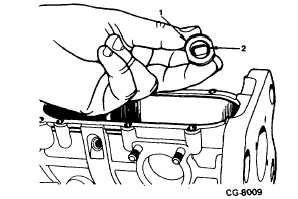

15.

Insert each plunger into correct barrel. Make

sure each plunger foot is positioned so that

notch on plunger foot points away from control

rack (Figure 5).

Figure 5.

1.

Notch on Plunger Foot

17.

Move rack back and forth and watch plungers.

The control rack should move freely without

binding and the plungers should rotate together.

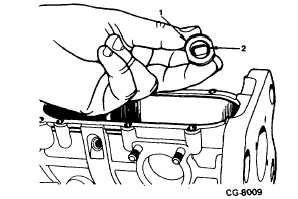

18.

Coat each lower spring seat with grease. Stick

lower spring seat on each roller tappet (Figure

Figure 6. Tappet and Spring Seat

1.

Tappet

2.

Spring Seat

CGES-375

Printed in United States of America

Page 2