SERVICE MANUAL

REASSEMBLY

Section 4

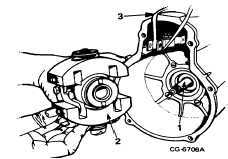

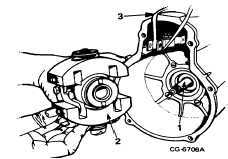

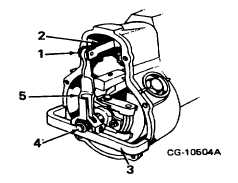

Figure 10. Installing Flyweight Assembly

1. Camshaft

3. Rubber Band or Wire

2. Flyweight Assembly

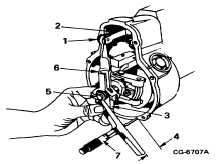

6.

Install slider and floating lever open slot of

floating lever to right. Pin floating lever to rack

link to hold in place.

7.

Check "slider-to-housing" distance with guide

bolt gauge 1 682 329 038 (Figure 11). Notch in

gauge must fit in groove on guide bushing when

gauge is placed against mating surface of

housing (no gasket)

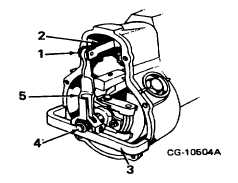

Figure 11. Slider-to-Housing Distance

1.

Pin

4.

Adjusting Pin

2.

Rack Link

5.

Floating Lever

3.

Guide Bolt Gauge

1 682 329 038

NOTE: If guide bolt gauge 1 682 329 038 is not

available use a depth micrometer to measure from back

of slider to governor mating surface (no gasket) (Figure

12). Distance (item 4) should be 39.15 i .2 mm (1.54 ±

.008").

Adjust by turning screw inside of guide bushing.

Back screw out to increase distance or turn

screw in to decrease distance (one half turn of

screw moves sliding block approximately .5 mm

(.020").

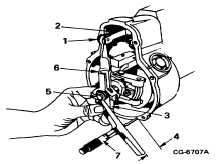

Figure 12. Measuring Slider-to-Housing Distance (If

Guide Bolt Gauge 1 682 329 038 is not available)

1.

Pin

5.

Guide Bushing

2.

Rack Link

6.

Floating Lever

3.

Slider

7.

Depth Micrometer

4.

Slider-to-Housing

Distance

8.

Secure double-nutted thru-bolt in governor

weight assembly by installing lockwasher and

nut. Bend over tabs of lockwasher to secure.

Operate rack back and forth to recheck all

linkage for free movement.

Remove seal cover from hi-idle adjusting screw

locknut on governor cover and back out hi-idle

adjusting screw. Hi-idle screw is removed so

that control lever can be moved full forward for

making next check.

Check "basic setting of S-plate", the distance

from governor cover surface (gasket in place) to

guide pin shaft when guide pin is in maxim fuel

position and bottomed in S-plate. Using S-plate

gauge 9 681 238 904 (Figure 13), notch in tang

of gauge should fit over guide pin shaft when bar

is placed on governor cover surface (gasket in

place).

CGES-375

Printed in United States of America

Page 5