SERVICE MANUAL

CALIBRATION

Section 5

INJECTION PUMP CALIBRATION

Following injection pump or governor service and

overhaul, the pump must be recalibrated to establish

correct internal timing, fuel delivery and governor

operation. It is also recommended that pump calibration

be checked on a calibrating stand anytime the injection

pump is removed to perform engine service operations.

IMPORTANT

FOR

PROPER

INJECTION

PUMP

OPERATION IT IS NECESSARY THAT

CALIBRATION

AND

ADJUSTMENT

CHECKS

ARE

PERFORMED

IN

SEQUENCE, AS OUTLINED IN THIS

SECTION.

NOTE: Refer to individual pump calibration charts and

data sheets (at end of this section) for specifications

mentioned throughout this section.

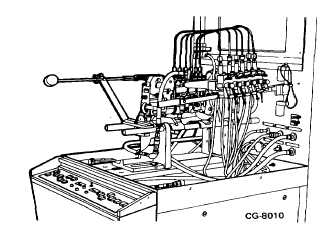

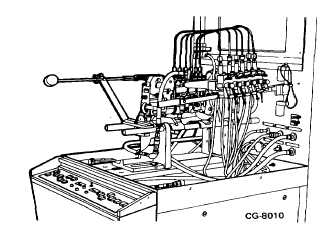

CALIBRATING STAND

A calibration stand with 10 HP or more is recommended.

Existing stands of 5 HP are acceptable.

When installing the pump on the test stand follow

instructions furnished with the stand.

Figure 1. Pump on Calibration Stand

Calibrating Stand Maintenance

The calibrating stand must be kept in good operating

condition. Maintenance checks and lubrication of test

stand components must be performed periodically to

assure satisfactory results. Calibrating oil must be of the

specified type. Calibrating oil and filter must be changed

regularly. Transfer (supply) pump must maintain

minimum specified pressure since injection pump

calibration depends upon correct supply pump oil

pressure.

To assure uniform delivery, calibrating stand test nozzles

should be tested for balance (equal delivery) every six

months or whenever 200 pumps have been tested. The

method for balancing the test nozzles is as follows:

a.

Adjust all test nozzles to specified test

nozzle opening pressure. (See Pump

Stand Manual.)

b.

Install an injection pump on calibrating

stand.

c.

Perform the "Maximum Fuel Delivery

Check" and record amount of fuel obtained

from No. 1 pumping element.

d.

Install each of the remaining test nozzles in

the No. 1 nozzle position and note delivery

from each nozzle. If necessary, adjust

nozzle opening pressure to obtain same

flow as recorded for nozzle No. 1 (Step c.).

Nozzles must be balanced to within 0.5cm3

per 1000 strokes.

e.

After nozzle balance (uniform delivery) has

been obtained, recheck opening pressure

of all nozzles. If nozzle opening pressure is

not within specified limits (3000 25 psi),

nozzle should be repaired or replaced.

MOUNTING ON STAND

Before mounting the pump on stand, make sure pump

camshaft can be rotated more then 360°. This is

especially important when the pump has been

overhauled.

When installing pump on stand follow instructions with

stand.

CGES-375

Printed in United States of America

Page 1