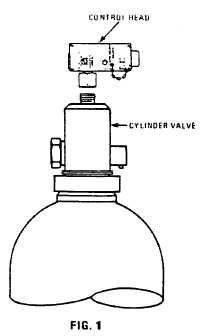

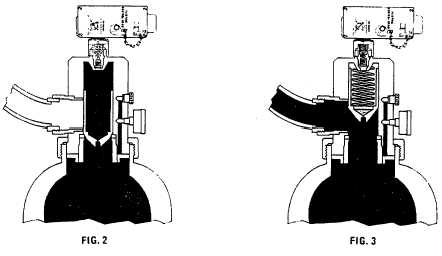

CONTROL & RELEASE EQUIPMENT

There are two principle parts in the control and release

portion of the system: (a) the cylinder valve, and (b) the

control head. See Figure 1.

Halon 1301 is stored in the steel cylinder as a liquid

which is super-pressurized by nitrogen to 360 psig at

700 F.

VALVE

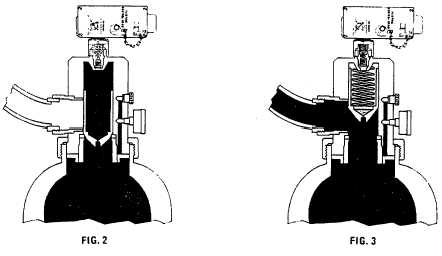

The discharge valve operates on a principle whereby the

cylinder pressure is used to effect the release of the

agent. In a normal standby situation, the pressure on

both sides of the valve piston is equalized by a small

interconnecting orifice through the piston. This provides

a differential force to hold the valve closed (See Figure

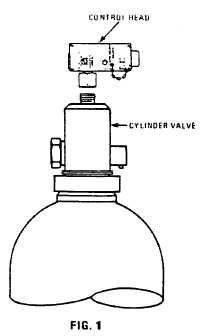

2). When the extinguishing system is actuated, the

control head which is mounted on top of the cylinder

valve depresses a pilot check. This allows the pressure

above the piston to vent rapidly to atmosphere, reversing

the differential pressure force. The piston is then driven

to the open position allowing the agent to be discharged.

See Figure 3.

The discharge valve incorporates a safety release burst

disc which is designed to release at 750-900 psig

through an anti-recoil plug to atmosphere.

Where the size or type of hazard requires more than one

cylinder of Halon 1301, the cylinders are manifolded

together. In these multiple cylinder installations of more

than two cylinders, a pair of cylinders is fitted with control

heads. These are known as control or master cylinders.

The other cylinders are called slave cylinders.

When the system operates, the Halon 1301 from these

control cylinders pressurizes the manifold connecting all

the cylinders thus releasing the content in the balance of

the cylinders. The pressure-operated or slave cylinders

are identical to control cylinders except they are not

fitted with control heads.

5