SYSTEM TESTING

The Kidde System not only features simplified testing,

but more important it features an arrangement which

permits the entire detection sequence of operations to

be tested easily and effectively. No replacement parts

are needed after test. Here is how it is done. (Applicable

to the electric and pneumatic systems.)

1.

Disconnect the control head from the

control cylinders. This simply involves

loosening

and

removing

a

union

connection.

2.

Place heat under the thermostats or

smoke around the ionization detector and

check that control heads have operated.

3.

Reset control heads before re-attaching to

cylinders. Reset control heads that are

attached to directional valves. This

arrangement permits detectors to be

tested without removing them from the

circuit. (Most detectors reset themselves

automatically. The electric control heads

require no replacement, simply resetting.

In this way you are assured that the actual

parts reinstalled have been given a

thorough test.)

APPROVED SYSTEMS

Kidde pressure operated systems are the result of many

years of development, research and retesting. The

equipment is fully listed by Underwriters Laboratories

and Factory Mutual Laboratories approved. Marine

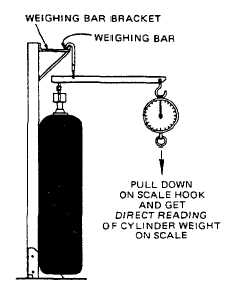

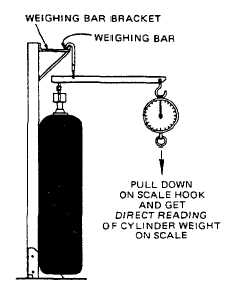

Systems are also U.S. Coast Guard approved. FIG. 15

Check these important advantages:

All operating parts completely enclosed;

not

subject

to

fouling

or

accidental

operation.

No falling weights.

No parts to replace after operation.

Visual inspection can determine if

cylinders have been operated.

All vital operating parts can be easily

tested.

Now, before fire starts, is the time to plan your fire

protection. When you have a Kidde built-in Halon 1301

system you have the best protection available, a quality

product, backed by the research, development and

manufacturing skills of the world's leading manufacturer

of Halon 1301 fire extinguishing equipment.

Kidde distributors, located throughout the world, are

always ready to serve you for all your fire protection

needs.

FIG. 15

9