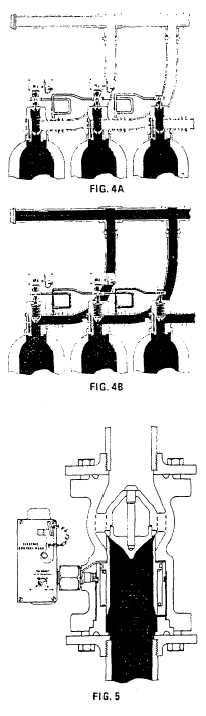

Figure 4A shows the position of parts on pressure-

operated cylinders ready to operate.

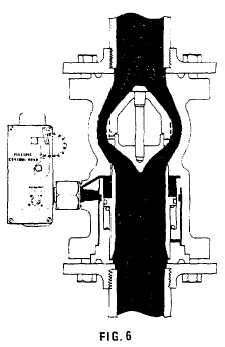

Figure 4B shows the parts during operation.

The pressure causes the piston to depress therefore

venting the upper cavity in the valve. Once vented, the

main seat opens automatically.

Figure 4A shows a typical multiple cylinder assembly

showing the manner in which the two control cylinders

are manifolded to the other cylinders in the system.

Note that Halon 1301 flows from the discharge flexible

loop to the pressure-operated control head.

Structural steel framing or racks are supplied with each

system for supporting the cylinders and manifold.

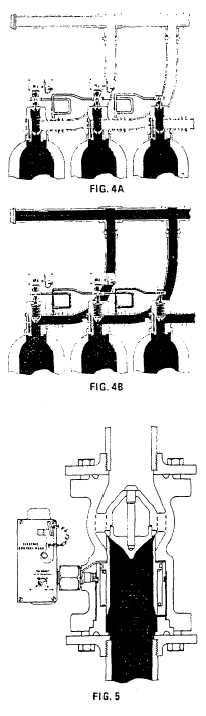

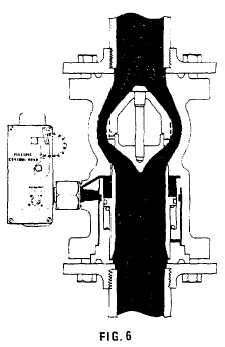

DIRECTIONAL VALVE SYSTEM

In some instances it may be necessary to protect more

than one hazard with the same bank of cylinders. In

these cases, pressure-operated stop valves are used to

route the Halon 1301 to whichever space in which a fire

occurs. These valves are available to complement the

cylinders' releasing equipment in order to permit

flexibility of installation.

When a fire occurs in one of the compartments with a

directional valve system, the detecting equipment via a

control panel performs the following functions:

1.

Opens the proper directional valve

2.

Releases the Halon 1301 cylinders

6