ELECTRIC OPERATION

The opening of the directional valve is accomplished by

fitting the directional valve with an electric control head.

Figure 5 shows the assembly of a pressure-operated

directional valve and an electric control head in its

closed position.

When the Halon 1301 being discharged reaches the

closed valve, it enters an auxiliary annular cavity around

the main valve seat. Figure 5 shows the location of the

pressurized gas which is dead-ended against the pilot

seat. Once the pilot seat is depressed by the electric

control head, the pressurized gas generates a force on

the piston which has been compressing the spring and

holding the valve closed. The valve, as a result of this

pressure, opens instantly.

The valve design is unique in the fact that it is an in-line

type having very little pressure drop across the seat.

Figure 6 shows the position of the parts of the valve

while the valve is open during operation.

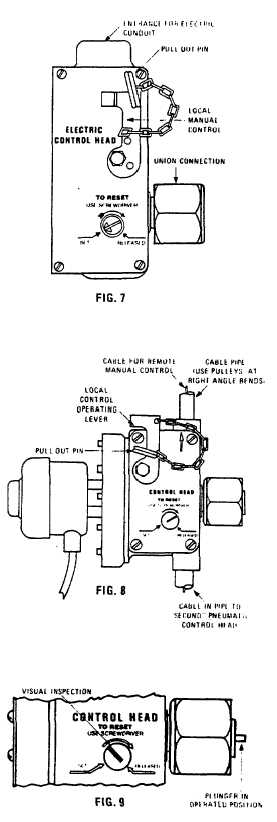

ELECTRIC CONTROL HEAD

The electric control head (see Figure 7) is available for

use with various voltages. When heat due to fire causes

the detector to close and complete the electric circuit,

electric energy operates a solenoid in the electric control

head which trips a lever mechanism releasing a spring to

drive the plunger forward to open the pilot seat. The

electric control head can be operated from a remote

point utilizing manually operated switch cases.

This control head includes an important maintenance

feature: it can be removed from the cylinders for check-

out. Visual checks can be made to verify actuation by

manually operating the system.

EXPLOSION PROOF ELECTRIC CONTROL HEAD

The explosion proof electric control head is available

with various voltages. It is suitable for use in Class 1,

Groups C & D type environments as specified in the

National Electrical Code.

The explosion proof head like the electric head is

operated by the movement of the solenoid that trips a

lever mechanism releasing a spring that drives a plunger

forward to open the pilot seat. See Figure 8.

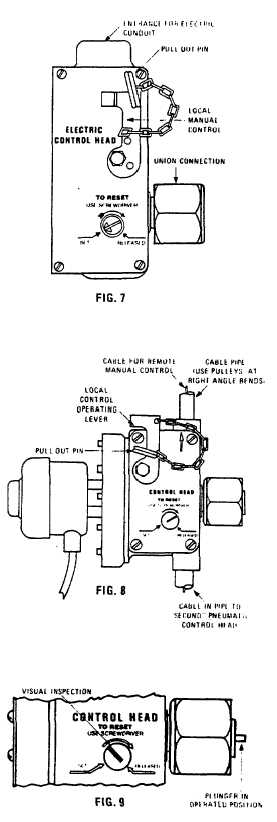

CONTROL HEAD INSPECTION

After operation, it is not necessary to replace any control

head parts. The control head is reset by using a

screwdriver to turn the reset shaft from "released"

position to "set" position. See Figure 9. The head is

also fitted with an emergency manual control. The

manual control can be utilized by pulling out the safety

locking pin, and then operating the lever.

An important advantage in the design of the control head

is that visual inspection is all that is needed to determine

whether the head has operated. If the reset shaft has

rotated to "released" position then the head has

operated.

In fact, no replacement parts are required to recondition

a discharged system at recharge.

7