SERVICE MANUAL

CYLINDER HEAD & VALVES

Section 3

CLEANING, INSPECTION & REPAIR

Clean Cylinder Head as follows:

1.

Remove deposites from UPPER and LOWER

DECK of head. Pay special attention to

EXHAUST VALVE PORTS, VALVE SEATS,

INJECTION NOZZLE SLEEVES and WATER

DIRECTORS.

a.

Use non-caustic solvent and BRASS wire

brush to clean bores.

b.

Blow out carbon deposits with compressed

air after cleaning. Clean Valves as follows:

1.

Remove residue from VALVE SPRINGS, VALVE

HEAD, STEM and BORES of VALVE GUIDE.

a.

Clean with suitable solvent and a BRASS

wire brush.

b.

Lightly polish valve surface with extremely

FINE emery paper.

NOTE: DO NOT USE STEEL BRUSHES these will

scratch the surface and lead to valve failure.

Clean Valve Guides as follows:

NOTE: Valve guides must be thorougly cleaned

prior to valve installation. Preform valve guide bore

cleaning on: 1. New service valve guides. * 2.

Valve guides installed in new service cylinder heads.

3. Valve guides presently installed in cylinder head,

which meet bore specifications.

Failure to clean valve guide bore can cause premature

valve guide wear and in severe conditions, valve

breakage.

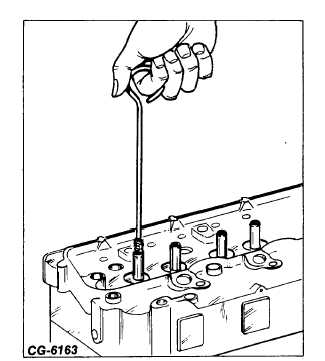

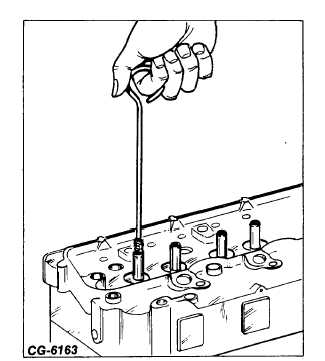

1.

Coat a nylon brush (which has a slightly larger

diameter than the l.D. of the valve guide) WITH

SOAP AND WATER.

2.

Insert brush Into I.D. of valve guide and with a

turning motion, run the brush through to insure

removal of gum, carbon, deposits and rust

preventive from the guide and spiral groove (See

Fig. 15).

Figure 15. - Cleaning Valve Guide Bores

3.

THOROUGHLY coat guide with clean engine oil

after cleaning operation is complete.

NOTE: When installing valves and retainers do not

use grease. Grease may stop the flow of lubricating

oil into the valve guide and cause valve guide wear.

*All valve guides furnished as service parts are reamed

to size; however, it is necessary to ream guides to

specified size after installation to remove any burrs or

slight distortion caused by the pressing operation. BE

EXTREMELY CAREFUL NOT TO REMOVE TOO

MUCH MATERIAL. Always clean guides after this

operation.

CGES-185-3

PRINTED IN UNITED STATES OF AMERICA

Page 15