SERVICE MANUAL

CYLINDER HEAD & VALVES

Section 3

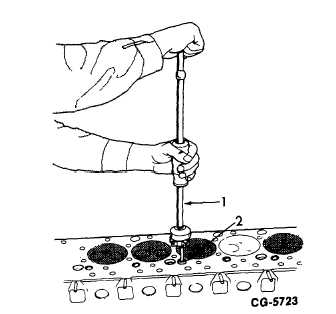

6.

Inspect cylinder head COOLANT DIRECTORS

for RESTRICTIONS or LOOSENESS.

a.

Visually check for RESTRICTIONS.

b.

Tap or pull directors by hand to check for

LOOSENESS.

c.

Remove

loose

or

restricted

coolant

directors. Use a slide hammer (1, Fig. 24)

with a small enough jaw to hook under

coolant director (2) "opening" as shown in

Fig. 24.

d.

New coolant directors should be tapped into

place with a small hammer and block.

They must be recessed 1.5 mm (.06")

below the bottom deck of the cylinder head.

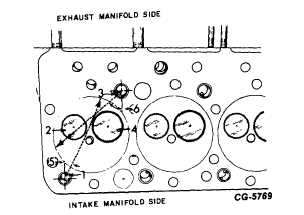

e.

Aim coolant directors at angles shown in

Fig. 25.

Figure 24. - Coolant Director Removal

1.

Slide hammer

2.

Water director

Figure 25. - Aiming Coolant Directors

1.

Coolant Director

2.

Exhaust Valve

3.

Coolant Director

4.

Intake Valve

5.

23Angle

6.

55Angle

7.

Inspect Valve Guides as follows:

a.

After cleaning ALL valve guide bores,

position a light at bottom of valve guide

bore; examine walls for burning, cracking or

excessive wear.

b.

Measure I.D. of valve guide at several

points. VALVE GUIDE I.D. LIMITS ARE:

9.500 mm (0.3740 in)

9.525 mm (0.3750 in)

c.

Replace any guides which are:

1.

Burned

2.

Cracked

3.

Worn Beyond Limits

4.

Without Rifling

d.

Remove valve guides with valve guide

remover (see Tool List for tool number).

CGES-185-3

PRINTED IN UNITED STATES OF AMERICA

Page 20