SERVICE MANUAL

CYLINDER HEAD & VALVES

Section 3

e.

Use valve guide installer (See Introduction

for tool list) to install new guide. Keep valve

guide recession from cylinder head surface

at limits specified below:

NOTE: Install valve guides with (internal) threaded

portion down. The 30 degree chamfer at the top of

the guide is Intended to allow excess oil to drain

away from the top of the guide and the threads are

intended only to distribute the small amount of oil

which enters the guide, not to introduce oil.

Inverting the guides can lead to excessive oil

consumption.

300 SERIES

Intake

Exhaust

25.20 mm (0.992 in)

32.31 mm (1.272 in)

25.70 mm (1.012 in)

32.82 mm (1.292 in)

400 SERIES

Intake

Exhaust

30.66 mm (1.207 in)

32.69 mm (1.287 in)

31.17 mm (1.227 in)

33.20 mm (1.307 in)

Inspect and Repair Valves as follows:

1.

Visually INSPECT each valve for excessive

WEAR, BURN MARKS, WAR- PAGE, PITTING

or SCUFFING at:

a.

Valve Stem Grooves.

b.

Valve Stems.

c.

Valve Heads

2.

Replace valves which are seriously bent, worn,

burnt, warped, pitted or scuffed.

3.

Resurface valve face angle, if necessary.

a.

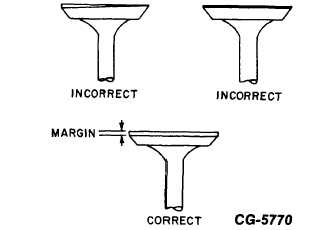

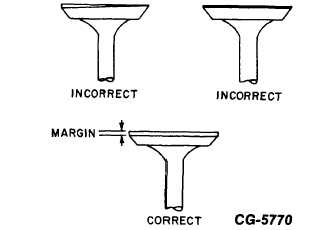

Maintain a minimum valve face margin of

1.73 mm (0.068 in) for intake valves and

1.14 mm (0.045 in) for exhaust valves on

300 Series engines.

b.

On 400 Series engines maintain a minimum

valve face margin of 2.24 mm (0.088 in) for

intake valve and 1.14 mm (0.045 in) for

exhaust valves. See Fig. 26.

Figure 26. - Examples of Valve Face Margin

c.

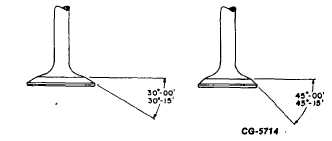

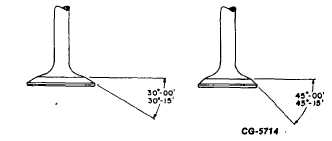

Maintain valve face angles as shown in Fig.

27.

Figure 27. - Valve Face Angles (300/400

Series)

NOTE: An incorrect margin will not provide proper

heat dissipation and lead to warpage or breakage.

4.

Resurface valve face angle as follows:

a.

Set valve in grinder to desired angle.

b.

Dress the wheel to proper angle.

c.

Take a light cut-off valve face angle

surface, as shown in Fig. 28.

CGES-185-3

PRINTED IN UNITED STATES OF AMERICA

Page 21