SERVICE MANUAL

CYLINDER HEAD & VALVES

Section 3

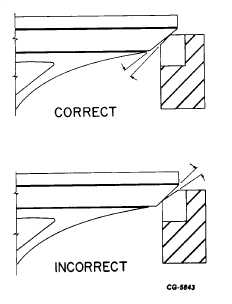

Figure 29. - Valve Seat Width

g.

Correct wide valve seats by grinding top edge of

seat with a stone mounted on grinder head. The

stone must be a smaller angle (preferably 1 5

degrees) than the valve seat.

NOTE: If valve does not seat properly after

resurfacing valve seats, replace valve seats.

6.

Replace valve seat as follows:

a.

Remove valve seats with a slide hammer

and expanding screw with pre-cup puller.

Two pre-cup pullers are available for

service one for intake, one for exhaust

valves. (See Tool List for tool numbers).

b.

Clean counterbore (in head), to assure

proper valve seat mating and good heat

transfer.

c.

If right fit is NOT assured between mating

surfaces of valve seat and cylinder head

counterbore, install oversize valve seat

inserts as follows:

1.

Take a light cut from bottom of insert

counterbore

in

cylinder

head

to

dimensions shown in the valve seat

insert chart for correct fit.

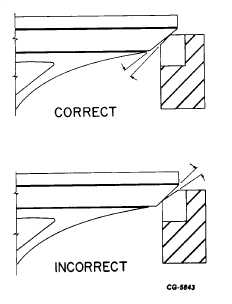

2.

Maintain radii shown in Fig. 30 when

enlarging counterbore for oversize

inserts.

VALVE SEAT INSERT CHART (OVERSIZE)

DIAMETER OF CYLINDER HEAD COUNTERBORE*

Oversize

Engine

Insert

Intake

Exhaust

Naturally Aspirated

002 in

None

38.96-38.99 mm (1.534-1.535 in)

312 and 360

**.005 in

None

3904-39.07 mm (1 537-1.538 in)

015 in

None

39.29-39 32 mm (1.547-1.548 in)

.002 in

45.19-45.21 mm (1.779-1.780 in) 38.96-38.99 mm (1.534-1.535 in)

Turbocharged 360

**.005 In

45.26-45.29 mm (1.782-1.783 in) 39.04-39.07 mm (1 537-1.538 in)

.015 in

45.52-45.54 mm (1.792-1.793 in) 39.29-39.32 mm (1.547-1 548 in)

All 414,

.002 in

50.75-50.77 mm (1.998-1.999 in) 41.30-41.33 mm (1.626-1.627 in)

436 and 466

**.005 in

50.83-50.85 mm (2.001-2.002 in) 41.38-41 40 mm (1.629-1.630 in)

.015 in

51.08-51 10 mm (2.011-2.012 in) 41.63-41.66 mm (1.639-1.640 in)

*It is not necessary to enlarge the Insert counterbore before Installing the standard size Insert.

** .005 Inch oversize Insert is no longer available for service.

CGES-185-3

PRINTED IN UNITED STATES OF AMERICA

Page 23