WHEELS, RIMS AND TIRES

Wiper Ring (Oil Lubricated Bearings)

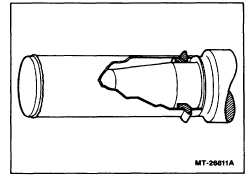

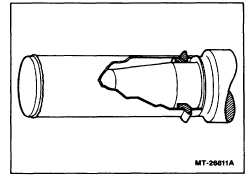

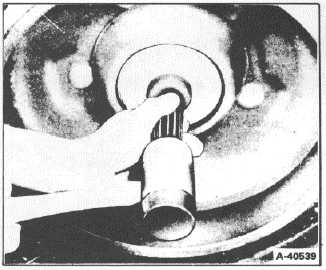

1.

Apply a thin coat of Loctite Gasket Eliminator

(purple) to shoulder on spindle or axle tube, and

place wiper ring on axle tube or spindle using an

installing tool (Figure 20). Remove excess

Gasket Eliminator sealant.

Figure 20. - Installing Wiper Ring on Axle Shoulder

The care with which the axle ring is Installed

cannot be over-emphasized. Damage to this

ring will result in shortened seal life.

2.

Tap on end of axle tool driving axle ring firmly on

shoulder until axle tool contacts shoulder.

3.

Check position of axle ring to make sure edge of

ring is parallel with shoulder.

Lip Type Seal (Grease Packed Bearings)

Lip Type Seal With Wiper Ring (Oil Lubricated

Bearings) - Not Guardian Oil Seals

The following instructions pertain to lip type wheel seal

used with grease lubricated bearings as well as lip type

seals with wiper ring used with oil lubricated bearings.

1.

Apply a thin coat of Loctite Gasket Eliminator

(purple) hub seal bore. The coating must be

very light, yet cover press fit area. Gasket

Eliminator should never be allowed to contact lip

of seal nor contaminate oil.

2.

Lay wheel flat on a steady surface with brake

drum up. Place inner wheel bearing into bearing

cup and place hub seal Into starting position on

hub.

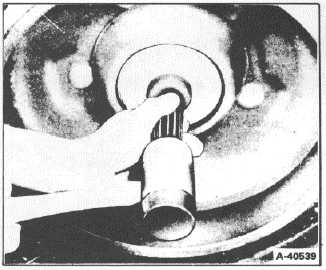

3.

Install hub seal using SE-1905 Installer Set to

prevent cocking seal (Figure 21). Select the size

disc which will apply force to outer edge of hub

seal and prevent seal from becoming distorted

or damaged.

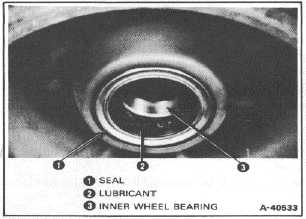

Figure 21.

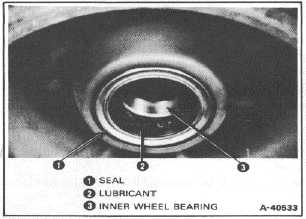

Drive hub seal into hub until it bottoms in hub bore. Do

not continue to drive after seal is once seated as this will

distort or damage the seal. After removal of seal installer

tool, clean off excess Gasket Eliminator. Be sure to

confirm uniform seating of seal (Figure 22).

Figure 22.

Unitized Scot Seal

1.

If seal is being changed to a unitized seal from

another type, remove wear rings if present. Do

not use a chisel to remove wiper ring since the

chisel could mar the axle. Use a ball peen

hammer and tap the ring lightly on the seal lip

surface. Do this in a small area, causing the ring

to expand, and allowing the ring to slip off the

axle housing.

CTS-4148A

Page 11