WHEELS, RIMS AND TIRES

2.

Apply a thin coat of Loctite Gasket Eliminator

(purple) hub seal bore. The coating must be

very light, yet cover the press fit area.

3.

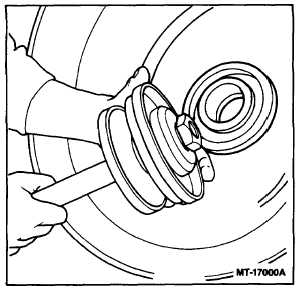

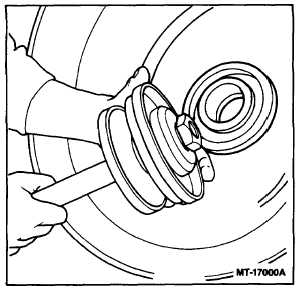

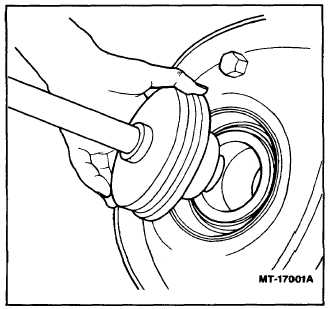

To install unitized seal in wheel, seat outer face

of seal in the recess of tool adapter (Figure 23).

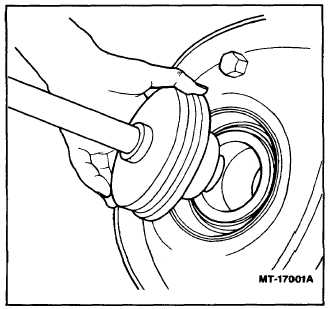

Insert centering plug of tool in bore of inner

bearing cone (Figure 24). Using the centering

plug aids in prevention of seal cocking in-wheel

bore.

Figure 23.

Figure 24.

4.

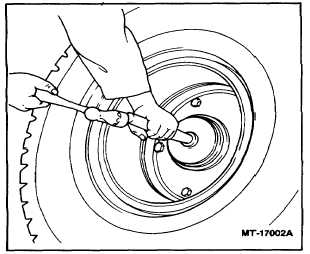

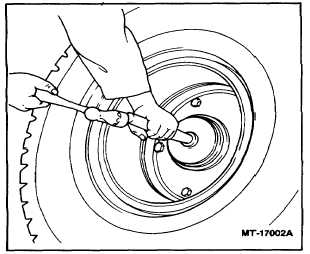

Hold tool handle firmly and strike until sound of

impact changes when seal is seated (Figure 25).

Then inspect seal to be sure it is uniformly

seated but not crushed. Remove excess

sealant.

Figure 25.

IMPORTANT Any time wheel Is removed with

a Scot Unitized Seal for any purpose, the seal

must be replaced.

A good check of proper seal installation is to

move the synthetic sealing member with your

fingers after installation in wheel hub. There

should be a slight in and out movement possible.

If wheel seal parts requirements require a wiper

ring installation, refer to installation of wiper ring

in preceding text.

Unitized Barrier Seal

The barrier type seal (Figure 18) is installed by hand and

new seals do not require any special lubricant or sealer

to outer or inner surfaces, except when new seal

appears to be free of lubricant. Then it is permissible to

wipe the leading edge of inside and outside diameters

sparingly with light bearing oil. These seals do not

require any special tools for installation.

Position seal over hub and use care so that the seal is

not cocked when pushed into place.

Push seal into the hub by hand until it is completely

bottomed and uniformly seated in the bore.

Do not use wheel bearing or chassis grease to install

seals, since grease could result in seal slipping in hub or

on spindle or axle tube.

CTS-4148A

Page 12