WHEELS, RIMS AND TIRES

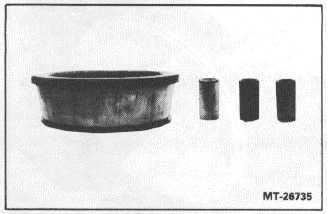

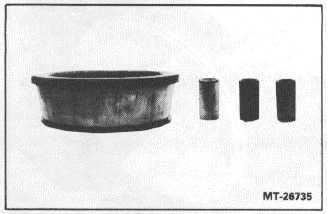

There is an etching or pitting on contact surfaces of cup,

cone or rollers (Figure 30).

Figure 30.

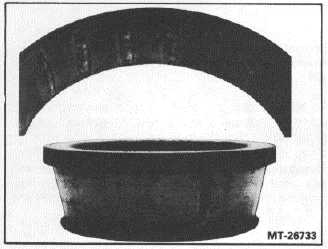

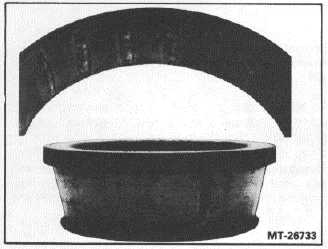

There is any spalling or flaking on either the bearing cup

and/or cone surfaces (Figure 31).

Figure 31.

LUBRICATION

Wheel bearings will either be grease or oil lubricated.

Refer to the LUBRICATION Section for type of lubricant

to use.

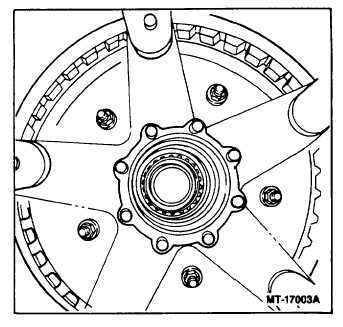

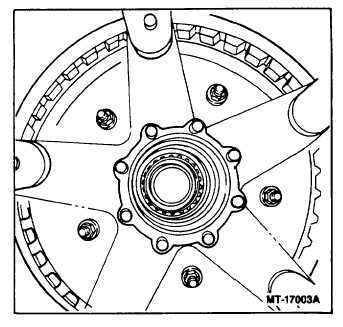

Always use a wheel dolly to place wheel(s) on spindle or

axle tube. Care must be taken so that the seal is not

damaged, especially when positioned over the end of the

spindle or axle (Figure 32).

Figure 32.

GREASE LUBRICATED

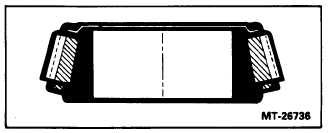

1.

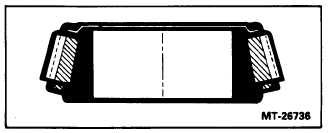

Pressure lubricate inner and outer bearing

assemblies, so that grease is forced between the

cone and cage until grease is expelled between

the cage and rollers (Figure 33).

Figure 33.

2.

Apply grease to wheel or hub cavity so that it is

even with inside diameter of bearing cups.

3.

Assemble bearings and seal and adjust bearings

as directed elsewhere in this section.

4.

When bearing maintenance is performed on rear

drive axle bearings, the procedures in oil

lubricated bearings can be used. It is important

that the rear axle lube level be inspected since

that lube also aids in lubricating the bearings.

CTS-4148A

Page 14