STEP 4/ FILLING AND BLEEDING THE SYSTEM.

This procedure requires two people.

Do not attempt filling and bleeding

alone, since it would be difficult for one

person to remove all the air from the

system. Failure to remove all the air

will result In spongy. unresponsive

steering.

NOTE: Using the funnel only, fill the

helm pump with SEASTAR outboard

hydraulic fluid. When the helm pump is

full of oil, screw the threaded end of

filler tube into the filler hole and Insert

the tunnel into opposite end of filler

tube.

CAUTION: During the entire bleeding

procedure, oil must always be visible in

funnel or filter tube. Do not allow the oil

level to disappear into the helm pump as

this may introduce more air into the

system, wasting fluid and making

bleeding more difficult.

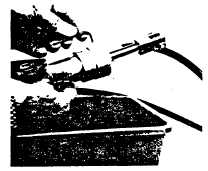

The second person is now required at

the splashwell area, equipped with a

clean rag, pan, and the Allen wrench.

Carefully fill the tunnel with oil

Tilt the cylinder so that the bleed

screw on the starboard (right) side is

higher than the port (left) side and

open starboard (right) bleed screw

(approximately 5 turns).

Turn steering wheel slowly to port (left)

side (1 turn per 15 seconds - turning

the steering wheel fast will cause air

and oil to mix, requiring several hours

of separation).

When air-free oil appears from bleed

screws, close bleed screw.

CAUTION:

Ensure that the steering wheel is

securely mounted to helm with washer

and nut, before attempting wheel

turning. Tighten nut to 150 IN/LBS (17

Nm). Do not exceed 200 IN/LBS (22 Nm).

Tilt cylinder so that the bleed screw on

the port (left) side is higher than the

starboard (right) side and open port

(left) bleed screw (approximately 5

turns).

Turn

steering

wheel

slowly

to

starboard (right) side (1 turn per 15

seconds).

When air-free oil appears from bleed

screw, close bleed screw.

Turn the steering wheel back and forth

slowly. Do not apply pressure when

resistance is felt at each hard-over

position. Stop the back and forth

movement by turning steering wheel

all the way to port (left).

Repeat bleeding the system as above.

Starboard side first - followed by port

side Only a slight amount of air should

appear this time.

The following step calls for removal of

excess oil in funnel and filter tube. Do not

ado more oil to funnel than necessary.

Open port (left) bleed screw.

Turn steering wheel to starboard

(right) side until oil lust disappears

from sight in filler tube

Close port (left) bleed screw.

A slight movement of the steering wheel

Should now cause movement of the

cylinder rod, indicating that the steering

system is properly bled. If at this time or

anytime in the future, the response from

steering wheel to cylinder rod is not

immediate, re-bleed the system.

Remove funnel and filler tube from

helm pump, and screw vent can onto

filler hole.

Ensure at all times that fluid level in

helm pump is at its correct level. If

any metal is visible through the filler

hole, add SEASTAR hydraulic fluid.

Use

only

SEASTAR

outboard

hydraulic fluid or Texaco aircraft oil

HO-15.

·

WARNING:

Check for leaks. Unchecked leaks

will lower the fluid level In the helm

pump to such a point that spongy.

unresponsive steering will result.

and in time could cause total loss of

steering.