SERVICE MANUAL

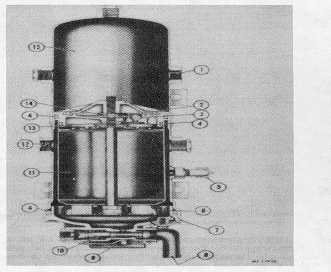

Fig. 3 Sectional View of AD-1 Air Dryer

1.

Outlet

2.

Nut

3.

Check Valve

4.

“O” Ring

5.

Safety Valve

6.

Oil filter

7.

Retaining Ring

8.

Exhaust Deflector

9.

Heater

10.

Purge Valve

11.

Desiccant

12.

Inlet

13.

Purge Orifice

14.

Jam Nut

15.

Purge Volume

Charge Cycle (Fig. 5)

With the compressor in its "loaded" or compressing

cycle, air from the compressor enters the air dryer

through the discharge line. When the air along with the

water and contaminants enter the air dryer, the velocity

or speed of the air reduces substantially and much of the

entrained liquid drops to the bottom or sump of the air

dryer. The initial air flow is toward the bottom of the

dryer, but air flow direction changes 180 degrees at the

bottom of the air dryer dropping some water and oil.

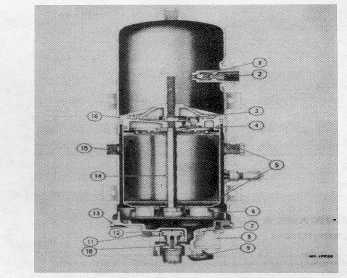

Fig. 4 Sectional View of AD-2 Air Dryer

1.

Check Valve

2.

Outlet

3.

Lock Nut

4.

Spring Retainer

5.

Perforated Plate

6.

Oil Filter

7.

Heater

8.

Thermostat Enclosure

9.

Electrical Terminal

10.

Purge Valve

11.

Control Port

12.

Purge Valve Piston

13.

Retaining Ring

14.

Cartridge Bolt

15.

Inlet

16.

Desiccant Sealing Plate

The air now passes through the oil filter which removes

some oil and foreign material but does not remove water

vapor. At this point, the air remains saturated with water.

The filtered air and vapors penetrate the desiccant drying

bed and the adsorption process begins. Water vapor is

removed from the air by the desiccant.

CTS-4079 - CHAPTER XIV - Page 4