TM 5-3825-229-14&P

5-9. FLYWHEEL AND RING GEAR (cont)

a

Removal (cont).

(1)

Remove six capscrews (1) and six flat washers (2) that secure flywheel to crankshaft.

(2)

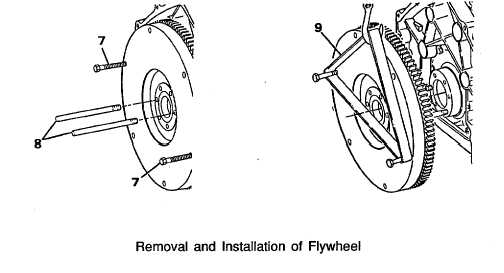

Install two long capscrews (7) in outer holes in flywheel face 180 apart (locations "A" and "B") to serve

as handles.

(3)

Install two M1 0 x 1.75 threaded rods (8) into flywheel mounting holes. These rods will support

the flywheel as it comes off the flywheel flange.

(4)

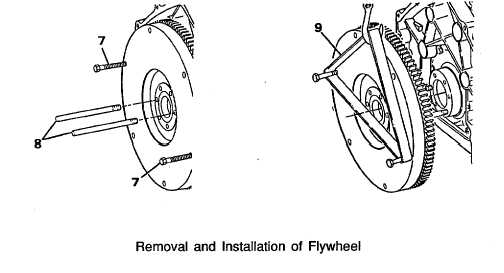

Install sling (9) on capscrews (7). Attach lifting device to sling.

(5)

Pull outward on two capscrews to remove flywheel (3).

NOTE

If flywheel cannot be removed with a direct pull and shaking of the handles, it may be

necessary to remove the starter and tap the flywheel loose. Rotate flywheel and tap

exposed area at intervals until flywheel comes loose.

(6)

Remove flywheel (3) with ring gear (4).

(7)

Remove sling (9). Remove rods (8) and capscrews (7) from flywheel and crankshaft.

b

Inspection.

(1)

Inspect flywheel surface where it mates to crankshaft flange, and remove any burrs or nicks.

(2)

Inspect ring gear for any cracked, chipped or broken teeth.

5-25