TM 5-3825-229-14&P

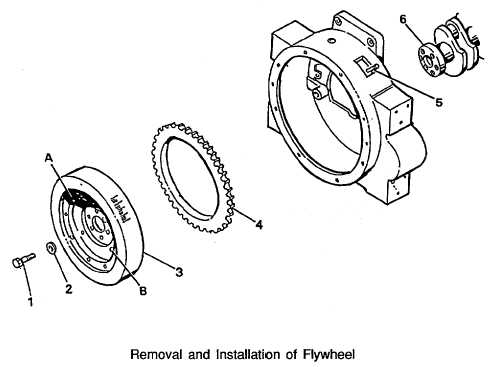

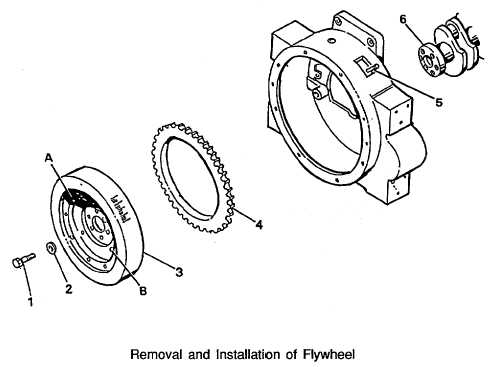

5-9. FLYWHEEL AND RING GEAR (cont)

c.

Disassembly.

(1)

Grind through ring gear (4) at base of one of the teeth until ring gear separates.

(2)

Drive severed ring gear off flywheel, using a hammer and drift.

d.

Replacement.

(1)

Heat new ring gear to 365-383°F (185-195C).

(2)

Quickly drive heated ring gear onto flywheel down against shoulder.

e.

Installation.

(1)

Install threaded rods (8) in crankshaft. Install long capscrews (7) in flywheel face. Attach

sling (9) and lifting device. Lift flywheel in position in flywheel housing.

(2)

Align alignment pin (5) and install flywheel (3) on crankshaft flange (6).

(3)

Install six capscrews (1) with six flat washers (2) in flywheel (3).

(4)

Torque six capscrews (1) to 50 lb.-ft (68 Nm) (wet) using a star pattern torque sequence.

(5)

Refer to para. 5-19 and install pump drive plate on flywheel. Refer to para. 5-6 and

install engine.

5-26