TM 5-3895-370-14&P

b. Cleaning/inspection.

(1)

Wipe off dust and dirt from tappet cover with cloth.

WARNING

·

Drycleaning solvent (P-D-680) is TOXIC and flammable. Wear protective

goggles and gloves; use only in a well-ventilated area; avoid contact with skin,

eyes, and clothes and do not breathe vapors. Keep away from heat or flame.

Never smoke when using solvent; the flash point for type I drycleaning solvent

is 100°F (38°C) and for type II is 140°F (60°C). Failure to do so may result in

injury or death to personnel. P-D-680 type III is a substitute for types I and II in

this application. The flash point for type III is 200°F (93°C).

·

If personnel become dizzy while using cleaning solvent, immediately get fresh

air and medical help. If solvent contacts skin or clothes, flush with cold water.

If solvent contacts eyes, immediately flush eyes with water and get immediate

medical attention.

(2)

Clean out opening in tappet cover and breather baffle with drycleaning solvent. Dry with lint-free cloth.

(3)

Check breather baffle for burnout and cracks.

(4)

Check tappet cover for cracks.

(5)

Replace all parts failing inspection.

c. Installation.

NOTE

Ensure tag saying "front" on gasket is facing engine block.

(1)

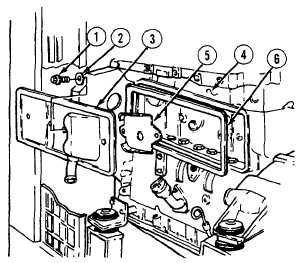

Install gasket (6) on tappet cover (3).

(2)

Install baffle breather (5) on tappet cover (3).

NOTE

Other two screws are installed with

fuel return hoses.

(3)

Install tappet cover (3) and two grommets (2)

with two screws (1). Tighten screws 18 lb-ft (24

Nm).

NOTE

Follow-on maintenance:

·

Install fuel injection pump (para

5-31).

·

Install fuel filter head (para 4-46).

·

Install fuel return lines (para 4-

41).

·

Install breather tube (para 4-27).

END OF TASK

5-57