SR 4 GENERATOR

DISASSEMBLY AND ASSEMBLY

clearance over the entire length of the supports.

This is especially important on generators with

long supports (10). Install shims as necessary

until all of the mounting surfaces are fiat and

parallel.

View A-A.

e.

Tighten all bolts that fasten the engine and

generator supports to the base to one-half of

their final torque. Loosen all bolts (7), and check

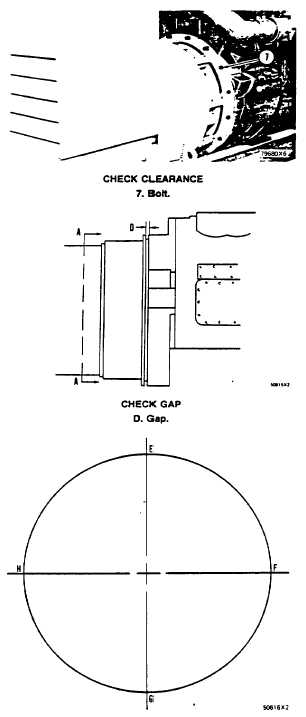

the gap (D) between the generator and the

flywheel housing at location (E), (F), (G) and (H).

Location (E) must always be at the top. Make a

record of each measurement.

f.

If the gap at location (E) is larger than the gap at

location (G) by more than .005 in. (0.13 mm),

install an equal amount of shims under each

generator support as necessary. If the gap at

location (G) is larger than the gap at location (E)

by more than .005 in. (0.13 mm), remove an

equal amount of shims from under each

generator support as necessary. After a

correction has been made to shim thickness,

tighten the generator support as necessary.

After a correction has been made to shim

thickness, tighten the generator support bolts to

one-half of their final torque and again check the

gap at location (E) and (G). Use this procedure

again and again until the difference in gap

measurements is .005 in. (0.13 mm) or less.

g.

If the gap at location (F) is larger than the gap at

location (H) by more than .005 in. (0.13 mm),

loosen the bolts in the generator supports and

move the rear of the generator to the right. If the

gap at location (H) is larger than the gap at

location (F) by more than .005 in. (0.13 mm).

loosen the bolts in the generator supports and

move the rear of the generator to the left. Do

this procedure again and again until the

difference in gap measurements is .005 in. (0.13

mm) or less. Tighten bolts (2) to their final

torque.

h.

Install a dial indicator on base (12) with the

indicator tip next to a support mounting bolt.

Tighten this bolt to its final torque, and at the

same time check the indicator. If there is more

than .005 in. (0.13 mm) of indicator movement,

the shim thickness is incorrect under that bolt.

Install shims as necessary. Do this procedure

again and again until all engine and generator

support-mounting bolts have been tightened to

their final torque and support deflection is within

specification.

142