SERVICE MANUAL

The cam ring can develop sharp edges from wear.

Use a clean shop cloth to remove cam ring to avoid

cuts. Remove ring by lifting straight up.

17.

Remove front end plate and discard gaskets. Remove

locating pin.

18.

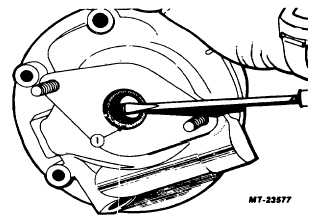

Remove housing-to-reservoir sealing gasket. Figure

21.

Fig. 21 Remove Gasket

1

Housing

2

Gasket

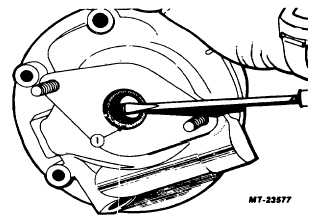

19.

Remove shaft oil seal with a screwdriver being careful

not to scratch seal bore or housing bushing, Figure

22.

Fig. 22 Remove Seal

1

Shaft Seal

CLEANING, INSPECTION AND REPAIR

Wash all components in a non-toxic solvent, air dry and

inspect individually as outlined below.

Component Inspection

Housing - Inspect drive shaft bushing in housing for

burning, scoring or oversize condition. The bushing is not

serviceable. If bushing is damaged, the housing must be

replaced.

Inspect ball plug located near the valve cap. If plug has

blown out, it can be driven back in to a depth approximately

6.35 mm (1/4 inch) below the cast surface.

Pump Cover - Inspect drive shaft bushing in cover for

burning, scoring or oversize condition. The bushing is not

serviceable. If bushing is damaged, replace cover.

Cam Ring - Inspect internal surface of cam ring for wear

or scoring. Polish in some areas is normal, but any wear

severe enough to raise a noticeable burr on the edge of the

cam ring I.D. indicates replacement is necessary.

Shaft and Carrier Assembly - Inspect carrier on the ends

of drive tooth faces for excessive wear or scoring. If ends are

worn or scored or wear pattern on any of the roll drive faces is

greater than 2.3 mm (.09 in.) in width, the carrier must be

replaced. Carriers are not serviced alone, but can be replaced

as part of a pumping element kit.

Inspect the shaft for any excessive wear, burning, or

scoring in the areas of the two bushings and the oil seal. If

any of these conditions exist, replacement is required.

Rolls - Inspect each of the twelve rolls for burning,

scoring, or wear on the O.D. surface. End Plates - Inspect

both end plates for wear, cracks or scoring on the surface

opposite

the

sealing

O-rings.

Any

scoring

indicates

replacement is required.

Flow Control Valve Assembly - It is difficult to visually

determine if a valve is defective. If the pump problem was

diagnosed as low pressure, and the pumping element shows

no sign of excessive wear, it is probable that the valve needs

replaced. The valve must fit and move smoothly in the valve

bore.

Pump Shaft Seal Installation

1.

Lubricate new shaft seal with same type of fluid as

used in pump. Place seal on top of seal bore with metal side

of seal upward.

CTS-4027 - Page 15